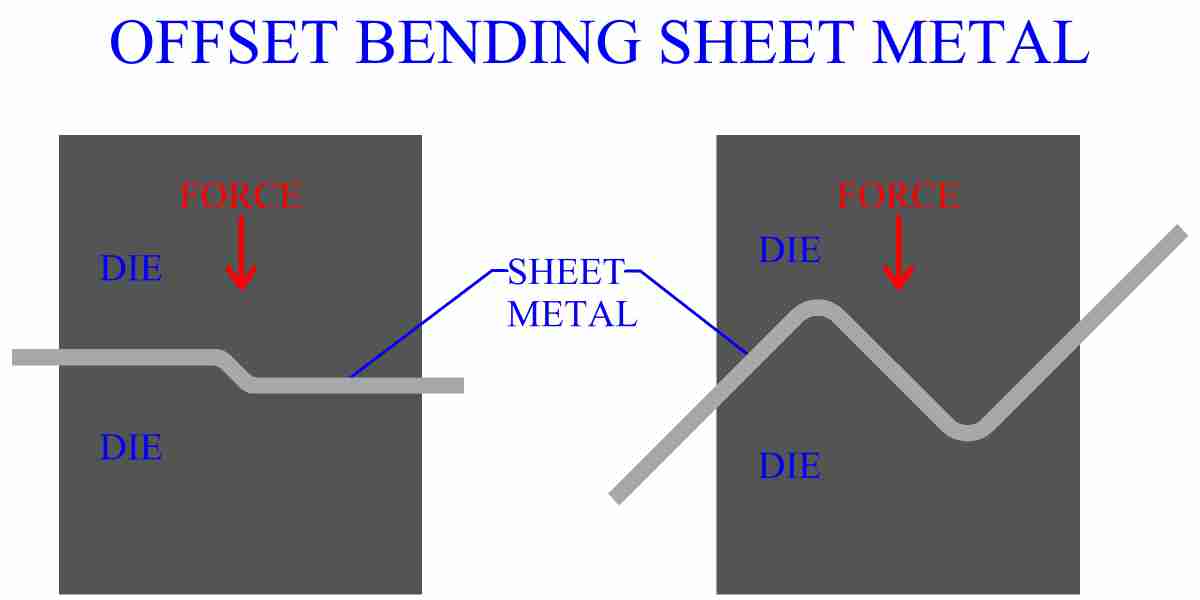

If left unsupported the material back bends meaning the material bends in the opposite direction of the bend the press brake tooling is performing.

Bend large sections of sheet metal.

Often several rolls may be employed in series to continuously bend stock.

The average hack requires at least one angled metal part and the best tool to make one is still the good ol press brake.

Roll forming of sheet metal is a continuous manufacturing process that uses rolls to bend a sheet metal cross section of a certain geometry.

This type of pattern on metal is made by a process called.

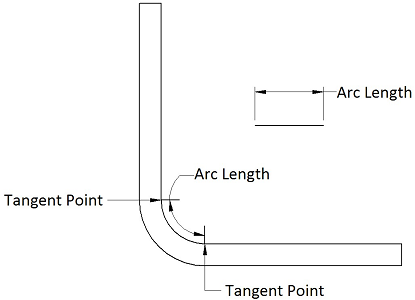

The resulting bend angle is influenced by the folding angle of the beam tool geometry and material properties.

Self tapping screws are primarily used when fastening objects to.

Which tool is used to bend large sections of sheet metals.

Simple sheet metal bender using a hand roller clamps and plywood.

Monkeys spinning monkeys by kevin macleod.

Anchor bolts are used to hold the.

Which tool is used to bend large sections of sheet metal.

The bend beam can move the sheet up or down permitting the fabricating of parts with positive and negative bend angles.

The best saw for accurately cutting 3 inches off the length of a 2x8x18 inch piece of lumber is.

On thin gauge panels a large section of material protruding from the press brake window during a small flange bend can pose a problem.

To bend sheet metal in a vice start by marking a line on the metal where you want to bend it.

Large sheets can be handled in this process making the operation easily automated.

If your sheet metal is long ask a friend to stabilize the part hanging out from the form blocks so it doesn t affect the bend.

Anchor bolts are used to hold the.

Rebar to the concrete.

Next put your wooden or metal form blocks in the vice and clamp your sheet of metal between the forms.