To create bends for small scale projects in plexiglass perspex or acrylic 1 8 inch and thinner you can use a small torch butane kitchen torches work well a paint stripping heat gun or an embossing heat tool which is a wand that works very similarly to a paint stripping gun but using a smaller more directed heat flow with a smaller fan.

Bending abs plastic sheet with heat gun.

Tutorial for how to.

Strong reusable our sheets can be re melted again and again so you can build reshape and add to your work as often as needed.

Forming a radius can also be done by using a heat gun using a back and forth motion across the length of the sheet both top and bottom until the material is soft enough to start bending.

Kydex can be easily cut to size by scoring and cutting sheets with a razor or similar knife.

If you re impatient you can also bend it yourself.

Heat create melt our plastic sheets with heat gun 150f and mold to any shape you like by using your hands or using tools.

Or do i need to have a two part mold with a top and a bottom.

The only absolute requirement for bending and forming kydex is heating the sheet until soft when the material becomes formable.

Is there a problem with going higher.

The spec sheet shows a temperature of 234 degrees.

Keep the gun at a distance of at least 8 to 12 do not get the heat too close to the material as blistering may occur.

Heat guns and toaster ovens have proven the best diy method for our customers.

Not a propane torch unless you ve done this before.

Heat it up with a heat gun.

For thicker sheets it will take longer and for thinner sheets it will take less time.

This article uses a sheet about 1 4 thick so all times are about 10 to 15 minutes per step.

Modify the timing as necessary.

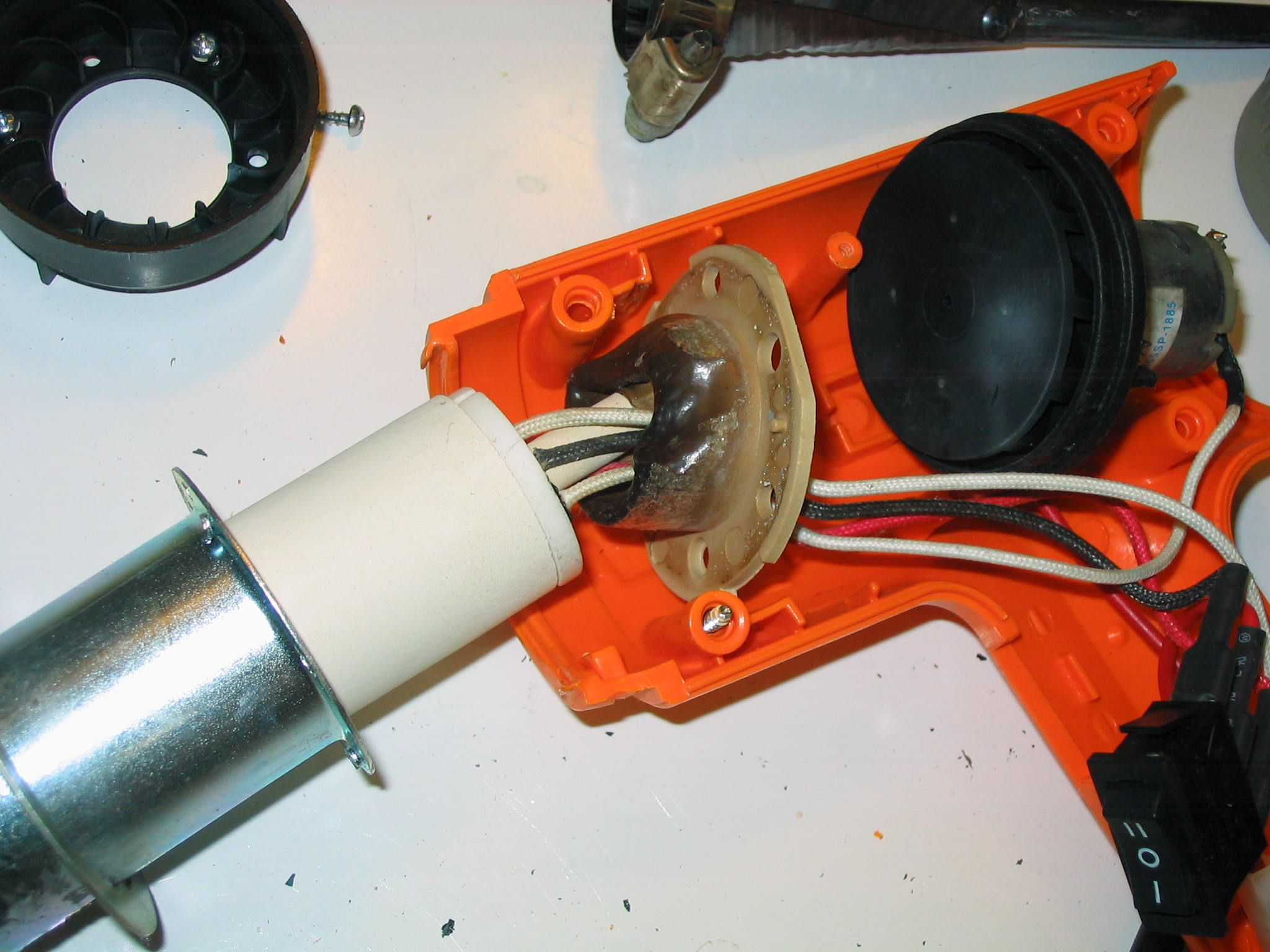

Preparing hot air gun w.

1 2 inch radius should be pretty easy.

Because plastic has a rather low thermal conductivity it takes a surprisingly long time to both heat up and cool down very easy to light the surface on fire while 1 8th inch below is still cold.

Ideal for perspex acrylic plexiglass polycarbonate.

This is my first attempt at oven forming abs plastic.

I have a wooden form and a piece abs plastic that i laid on top of the form.

If you wait long enough it will bend along the table or foam.

To bend abs lay the piece on the edge of a table or the foam part and heat up the part where it needs to bend.

Cut out different shapes from the sheet.

The only major variable that can affect the forming process is the thickness of the plastic sheet.

When the texture of the abs changes slowly push the abs down.